News

Interview on Power Modules for inverters by KYOCERA AVX Components

Power Modules for inverters by KYOCERA AVX Components provide highest efficiency and reduction of weight as well as space requirements by using SiC and GaN

KYOCERA AVX Salzburg partners with Nexperia to produce a 650 V silicon carbide rectifier module for power applications

Joint collaboration on SiC modules brings the next step in module compactness and maximum power density KYOCERA AVX Components (Salzburg) GmbH, a leading international supplier

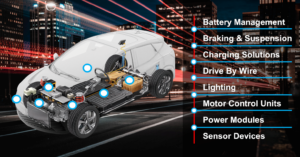

Electromobility – Sensors and Controls

As Electromobility gains more importance, KYOCERA AVX Components is actively involved and support our customers with the environmentally friendly alternative to conventional vehicles offering solutions

KYOCERA AVX Salzburg and VisIC Technologies expand their collaboration within e-mobility on next-generation GaN technology

Ness Ziona, Israel/ Salzburg, Austria 26/10/2022 Combining KYOCERA AVX’s leadership in discrete and module packaging along with VisIC’s expertise in GaN power devices to offer

TISAX certification for KYOCERA AVX Components

Locations in Werne and Klingenberg already suceeded – Salzburg will follow soon. Data exchange with maximum security is a core requirement in the automotive industry.

Partnership with Nexperia agreed

KYOCERA AVX Components (Salzburg) GmbH and Nexperia agree Partnership for Gallium Nitride Automotive Power Modules. Over 30 years of delivering application-specific power electronics to the

Career at KYOCERA AVX Components (Dresden) – Let’s meet!

As a sponsoring partner or as an exhibitor, we are regularly present at events, because we want to get to know you! The formats are

Proven pedals for future truck generations

Leading European manufacturer KYOCERA AVX Components has launched the latest series of accelerator pedals for trucks – and they’re all set for whatever demands the

Change of AB company names

Our companies are being globally integrated into KYOCERA AVX Components starting on October 1st 2021. This process will go along with names changes in our